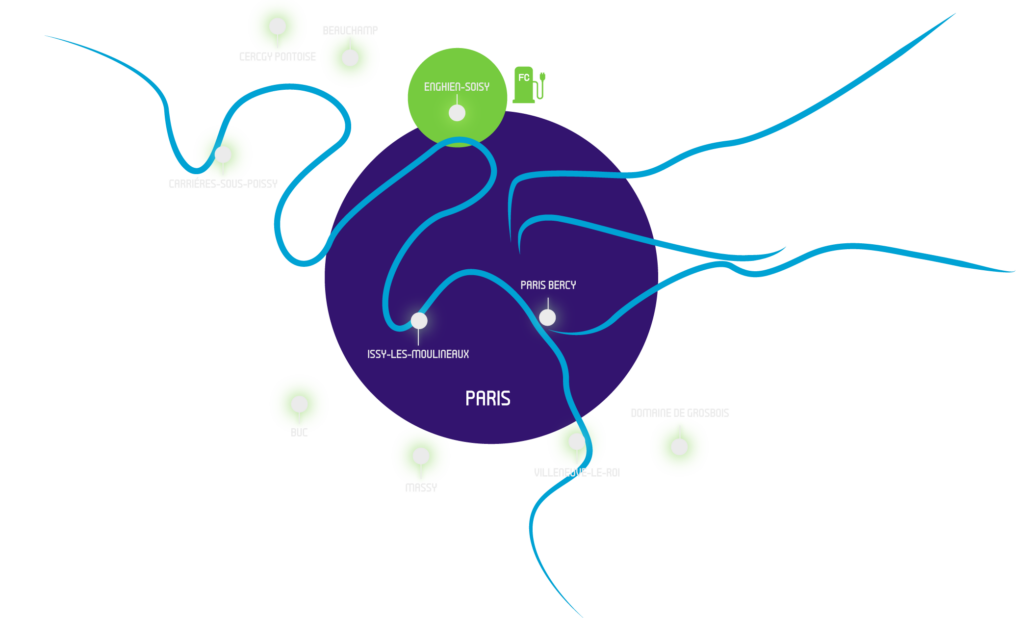

End to end demonstration:

Advanced hydrogen compression

The metal hydride compressor designated for installation at the HYGHER filling centre is engineered to compress 1.8 tons/day of hydrogen from 25 bar to 500 bar. This solution will be CE certified in the scope of the project, underscoring its compliance with stringent safety and performance standards.

- Modular design: The system’s modular configuration ensures scalability and flexibility to meet varying hydrogen compression requirements.

- Reliability & maintenance: The absence of mechanical moving parts significantly enhances system reliability and reduces maintenance costs.

- Waste Heat Utilization: A standout feature of the metal hydride compressor is its ability to utilise waste heat sources, improving the whole hydrogen value chain efficiency.

High-capacity tube trailers

For high-capacity hydrogen transport, RECOMA will manufacture two innovative high-pressure Multiple-Element Gas Container (MEGC) trailers capable of each transporting 1,250 kg of hydrogen at 500 bar. Leveraging its advanced expertise in MEGC and tube trailer manufacturing and a robust supply chain of cylinders and other components’ producers, RECOMA will design these new MEGC tube trailers with innovative cascading concepts for optimised filling and unloading. The goal is to store and transport the maximum amount of hydrogen safely and efficiently.

- Multiple-Element Gas Container: The MEGC made with Type IV cylinders and maximising hydrogen load capacity up to 1,250 kg, significantly reducing travel frequency and pollution.

- Cascading System: The MEGC is divided into independent sections to create a cascade system, ensuring optimal filling and unloading processes.

- Flexible Chassis: Designed for easy maintenance, the flexible chassis prevents immobilisation, enhancing operational efficiency.

Comprehensive value chain integration

Safety in HYGHER

Safety plan: A meticulous safety plan will be developed, serving as a guideline for all project phases. Key elements include:

- Ensuring all manufacturers comply with stringent safety requirements.

- Compliance to all European and national regulations, codes, and standards.

- Thorough Safety Studies for all developed subsystems and detailed safety assessments at all demonstration sites.

A Safety Blueprint will be prepared to provide a global perspective on the hydrogen supply chain. This overarching approach will integrate all safety aspects into a cohesive overall safety concept and focuses on potential interactions and interdependencies between individual subsystems and sites.

This supply chain safety concept will facilitate the sharing of best practices within the hydrogen industry and provide recommendations to support the broader deployment of high-pressure hydrogen supply.

Sustainable innovation

HYGHER is dedicated to enhancing the sustainability and resilience of the EU hydrogen supply chain through improved efficiency, circularity approaches, and reduced reliance on critical raw materials. The project ensures the sustainability of its innovative value chain by conducting environmental Life Cycle Assessments (LCA) and exploring circularity strategies such as material choices, recyclability, and second-life applications. Key contributions to sustainability and resilience:

- Whole Value Chain free of Critical Raw Materials: The metal hydrides developed by EIFHYTEC are free of rare earths, ensuring geopolitical independence and supply chain resilience.

- Reduced Standard Materials: Enhanced kinetics and composition of hydrides minimise the use of steel and metal alloys in compressor construction. Additionally, refuelling stations capable of using 500-bar trailers as storage directly connected to dispensers optimise steel usage for storage.

- Second-Life Strategies for Trailers: Exploring opportunities to re-qualify and repurpose trailers for other applications, promoting sustainability through extended product lifecycles.

To achieve these goals, the project includes:

- Detailed assessment of environmental impacts at the component level to identify circularity potential and improve resource efficiency.

- Comprehensive Environmental Life Cycle Assessment (E-LCA): of the HYGHER supply chain and benchmarking against existing hydrogen distribution systems to validate sustainability improvements.